About Us

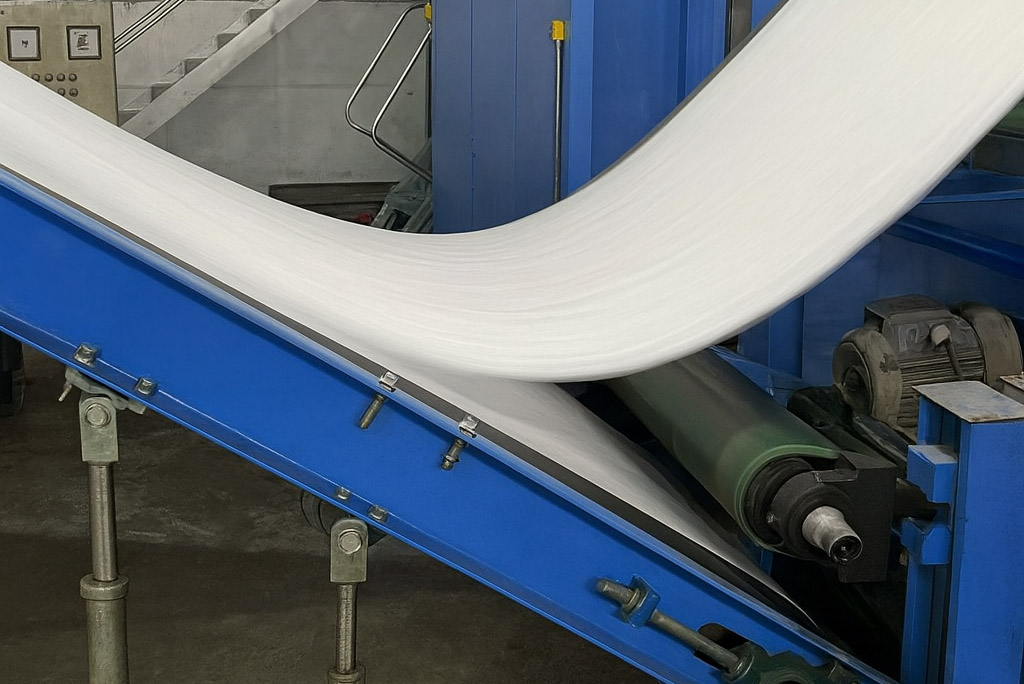

Local Manufacturing

We are proud to support design and manufacturing in Türkiye. Over 90% of our textile and acoustic products are produced locally.

Our History

Founded in 1917 as a textile-focused venture, Gentuğ has grown far beyond woven fabrics—evolving into a leader in decorative acoustic solutions. Our journey represents a unique blend of textile heritage and advanced acoustic innovation. From looms to acoustic landscapes, each step reflects a deliberate commitment to design, quality, and progress.

Over the years, we have embraced a future where uniqueness meets performance—creating modern decorative acoustic products that enhance interiors and redefine aesthetic standards.

Today, Felt Vibe® stands at the intersection of textile legacy and acoustic ingenuity. Our story is one of transformation: where the threads of the past seamlessly weave into a vibrant acoustic future—offering decorative acoustic panels, sound insulation, and thermal insulation solutions.

Felt Vibe® global design, local production

Our state-of-the-art research and development facility is supported by a strong team of industrial designers, product engineers, and acoustics specialists. With three dedicated production facilities, comprehensive sales and project (specification) teams, and a local support network available in many countries across four continents, we aim to deliver an innovative experience worldwide through our products and solutions.

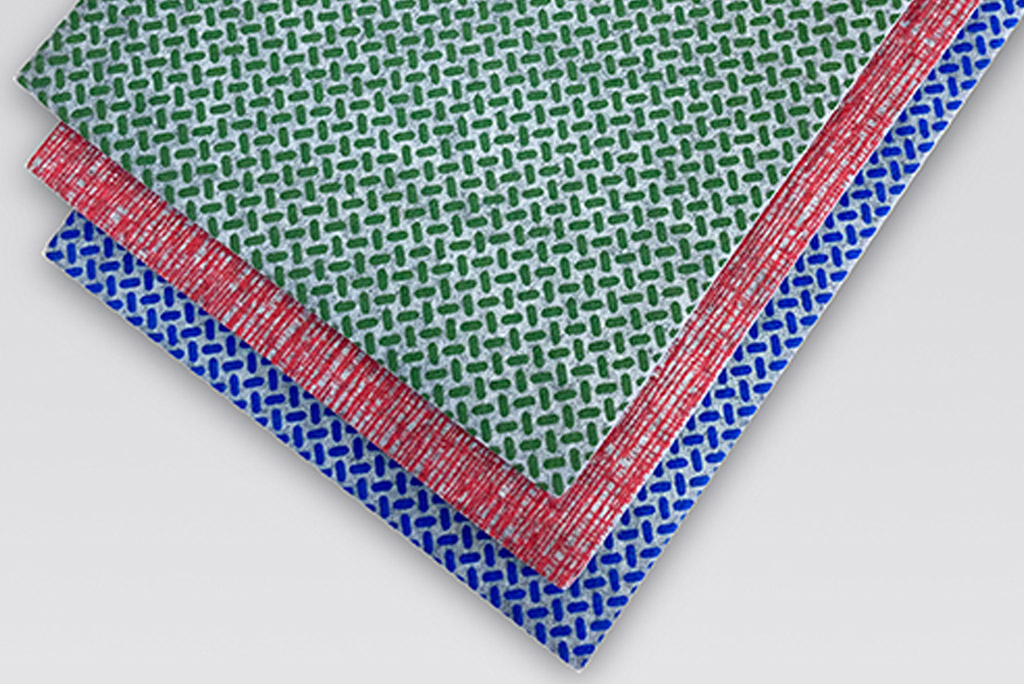

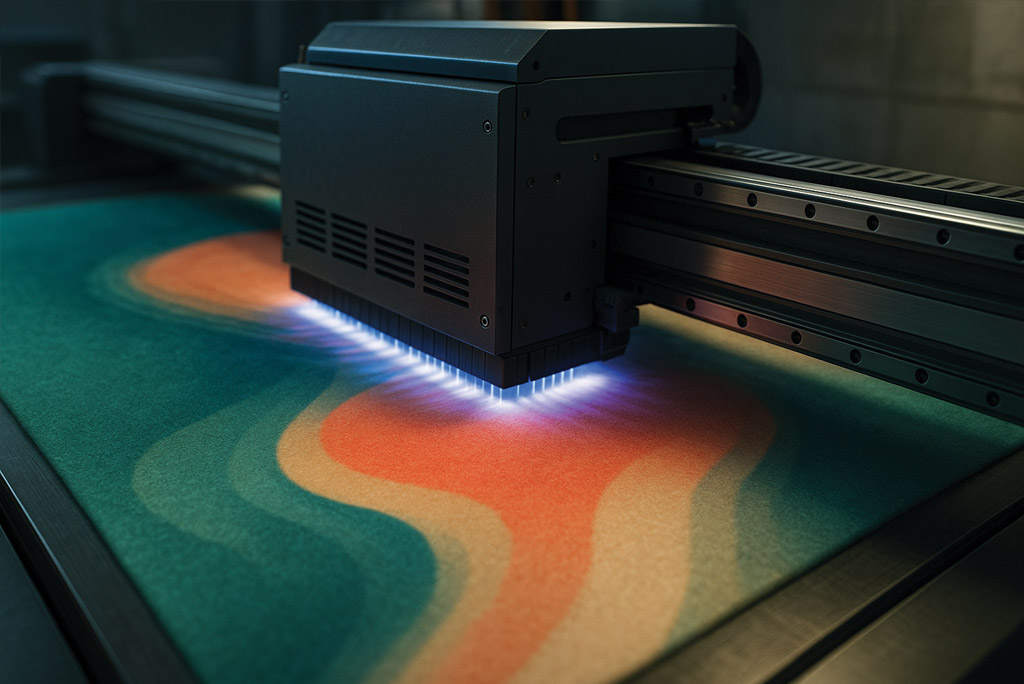

Felt Vibe® produces design-driven architectural acoustic solutions. Our PET felt raw material offers outstanding acoustic performance and, thanks to its fully customizable structure, supports a wide range of applications from ceilings and walls to divider systems and furniture.

We collaborate directly with architects, interior designers, fit-out and renovation companies, as well as global brands. We provide our local partners with high-performance products made from PET felt. Thanks to the flexibility of our material, we can offer a wide variety of design alternatives, rich color options, and bespoke printing capabilities.